Is HPL a laminate?

Is HPL a laminate? Many people have this kind of question. HPL boards, also called fire boards, are very common in today's interior decoration applications. They can be used on kitchen countertops, public bathroom partitions, office cubicles, and even on the table of your favorite restaurant. . It may be one of the most functional and ubiquitous materials in residential and commercial design. But despite the widespread use, there are still many people who don't know enough about it. So today, Xiaobian will tell you about HPL laminates;

What is HPL?

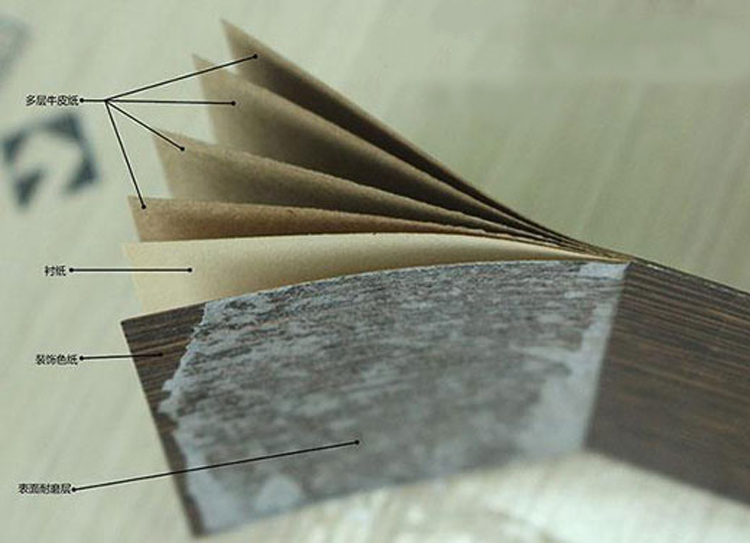

The full name of HPL is "Decorative High-pressure Laminate", which is generally called fireproof board in China. The main raw material of the board is paper and resin. The multi-layer paper is impregnated with resin and made of high temperature and high pressure. The styles are diverse and the performance is excellent. Suitable for a variety of environments;

What is a laminate?

The official definition of a laminate is "an artificial decorative material applied to the surface of a substrate." It is commonly referred to as HPL or high pressure laminates, but its technical name is a thermoset high pressure decorative plastic laminate. Laminates have many features that can be used extensively: it has hundreds of designs, low maintenance, heat and impact resistance, and high investment value. So it can be seen from this that HPL is actually a kind of laminate;

Laminates are manufactured in two ways: high pressure or low pressure

HPL is the most commonly used laminate. They consist of a multilayer resin treated paper that is fused together during manufacture. HPL can be adhered to a variety of substrates, has similar dimensional characteristics to wood, and can expand and contract with humidity. They are suitable for any application requiring durability and impact resistance, for vertical and horizontal surfaces, with low initial cost and a service life of 5 to 15 years. HPL also offers hundreds of designs and a variety of surface finishes.

Low pressure laminates (LPL) are also known as melamine sheets or direct pressure laminates. They consist of a single layer of wear on a single decorative panel and are only recommended for vertical surfaces or low impact/low flow areas. The initial cost of LPL is very low, but only one to five years of life. They offer a limited amount of design and surface treatment.

Laminate design

When choosing a laminate for your project, there are more factors to consider besides color and design. Designers must also determine the type of laminate, texture, edge treatment, and substrate or post-forming requirements. In most cases, these decisions are based on the product's performance needs, budget, and intended use.

Many people are unaware that there are several types of HPL available. HPL is usually divided into several product types: general purpose, vertical surface, post-forming, flame retardant, high abrasion resistance, chassis liner and backing. Most laminates fall into the general category. Universal laminates can be used for both horizontal and vertical surfaces where the surface must be functional, decorative and durable, such as a residential kitchen countertop or countertop. Vertical surface laminates provide decorative and functional surfaces for walls or surfaces with minimal impact and wear, while columnar laminates are compatible with heating and bending processes, forming a laminate on the radius to eliminate seams.

There are more than 90 different types of specialty and performance laminates. Each product was developed to meet specific performance needs, such as ultra-thick laminates that do not require a substrate, ultra-thin laminates used in cabinets, or double-sided laminates with double-sided decorative surfaces. Other specialty laminates are designed for specific environments, such as hospitals or buses.

As the name implies, chemically resistant laminates are resistant to common chemicals. It can be used in hospitals, laboratories and other areas where various chemicals or detergents are used. The impact resistant laminate comprises a core made of aluminum or steel and can be used in public transportation vehicles, light industrial facilities and offshore interiors. Wear resistant laminates are produced for commercial, contract, and institutional applications that require the decorative surface to withstand more wear than normal wear. They have six times the abrasion and wear resistance of conventional laminates. Another specialty laminate is a refractory laminate for indoor applications requiring decorative surfaces to withstand flames and fumes in the event of a fire.

Once the type of laminate is selected, color, design and texture should be considered. Most laminates have standard products with 200 to 250 design choices, and textured finishes add more options. Some manufacturers have a limited access to non-standard design libraries, including forms of development for selected product models added to large customers. These designs typically have longer lead times and higher charging times. Custom designs or colors are added to customers outside of standard HPL products, and the entire development process takes three to five months.

In addition to hundreds of colors and designs, laminates are available in a variety of textures. Most of these textures are made of stainless steel, but some special finishes require the use of textured foil. The surface treatment not only changes the appearance of the laminate, but also affects the abrasion resistance of the laminate, so the use and location of the laminate texture should be considered when making the selection.

It's important to remember that some textures look more scratch-resistant than others when choosing colors or textures. For example, glossy textures are more likely to show scratches than matte textures. The more surface texture, the more resistant it is to scratching - the texture can actually "break" the scratch. In addition, certain colors and patterns are considered to minimize the appearance of normal wear. Scratches are not easily visible on lighter colors than on dark ones, and general wear and stains on the pattern are not as visible on solid colors.

The laminate is always specified under the lighting conditions that match the final installation. Although very careful in the quality control of paper used in laminate production, some colors may have metamerism.

+86 18866930785 +86 15265936035

+86 18866930785 +86 15265936035