Melamine Plywood

|

Product Name |

Melamine Laminated Plywood |

||

|

Size |

1220x2440mm, 915x2135mm or as clients requirement |

||

|

Thickness |

2~36mm |

||

|

Thickness Tolerance |

+/-0.2mm |

||

|

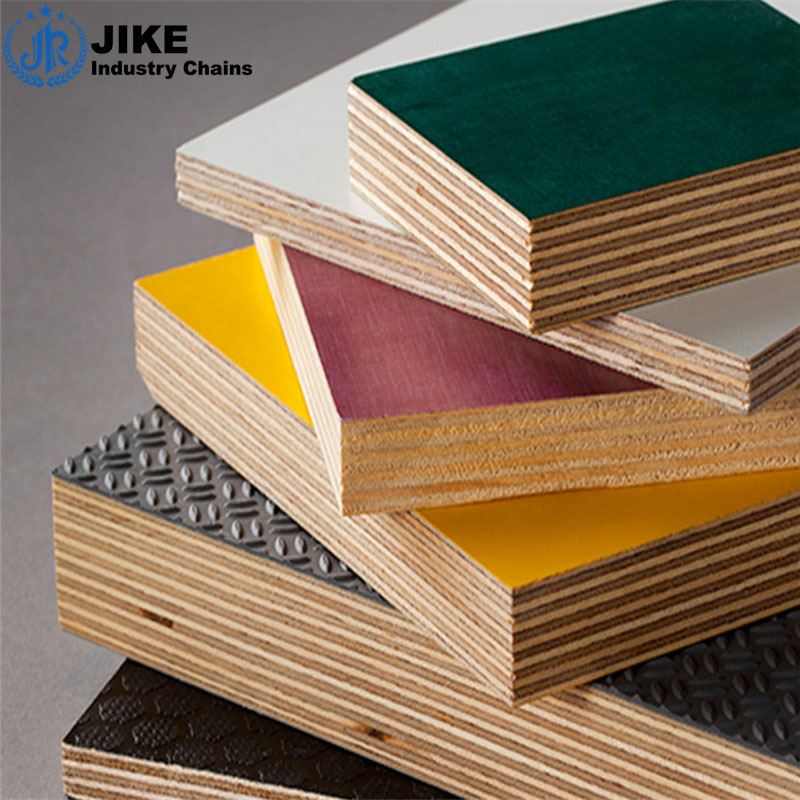

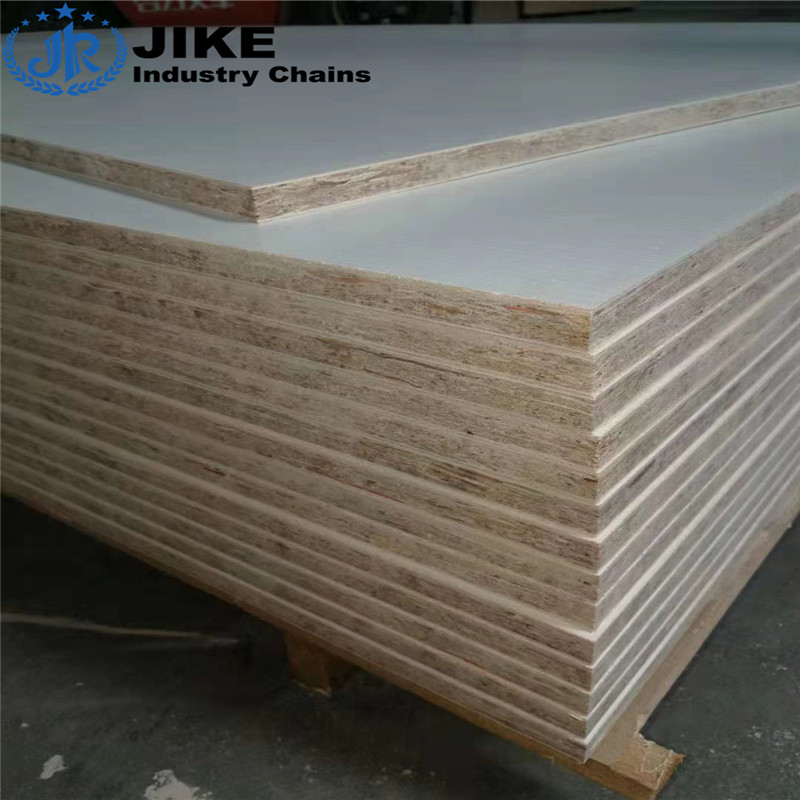

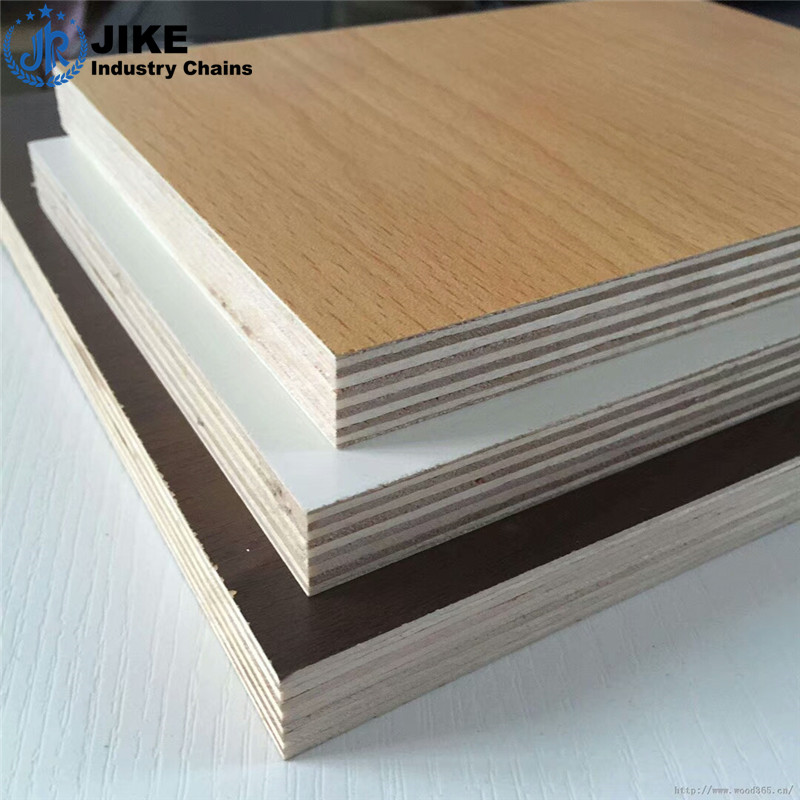

Face/Back |

Melamine faced (one side or both side melamine faced) |

||

|

Surface Treatment |

Embossed (There also have matt, textured, glossy or magic) |

||

|

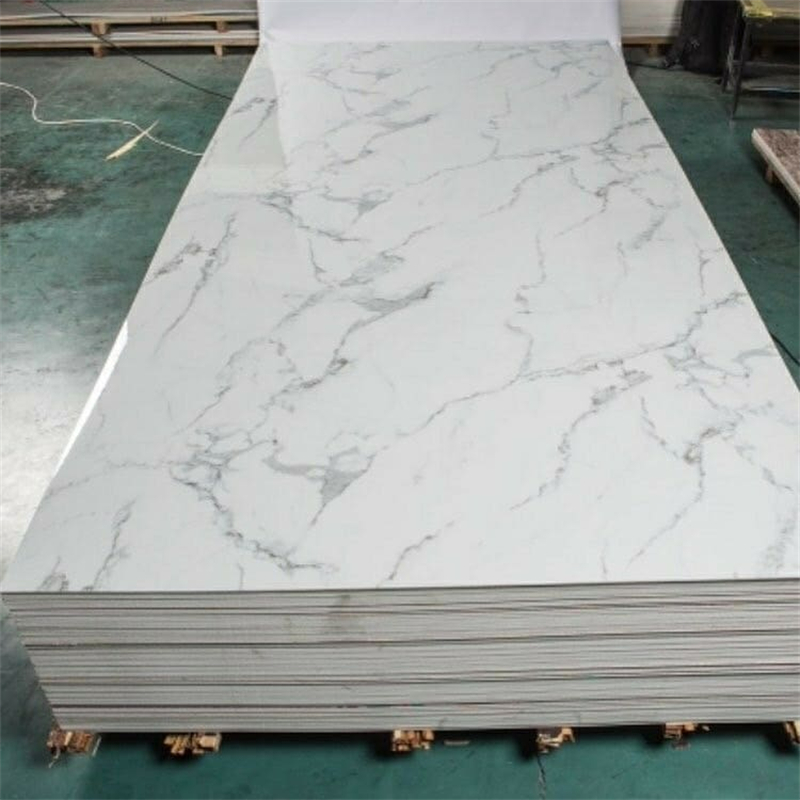

Melamine PaperColor |

Solid color (such as grey, white, black, red, blue, orange, green, yellow, ect.) & wood grain (such as beech, cherry, walnut, teak, oak, maple, sapele, wenge, rosewood, ect.) & cloth grain & marble grain. More than 1000 kinds color are available. |

||

|

Melamine Paper Gram |

80~120g/m2 |

||

|

Core Material |

poplar, pine or combi,hardwood,birch |

||

|

Glue |

E0, E1 or E2 |

||

|

Grade |

A grade or as clients requirement |

||

|

Density |

530~660kg/m3 |

||

|

Technical Parameters |

Moisture Content |

≤8% |

|

|

Water Absorption |

≤12% |

||

|

Modulus of Elasticity |

≥2500Mpa |

||

|

Static Bending Strength |

≥22Mpa |

||

|

Surface Bonding Strength |

≥1.20Mpa |

||

|

Internal Bonding Strength |

≥0.55Mpa |

||

|

Screw Holding Ability |

Face |

≥1300N |

|

|

Edge |

≥800N |

||

|

Usage & Performance |

Melamine Plywood is widely used for furniture, interior decoration and wood flooring. With good properties, such as, acid & alkali resistant, heat resistant, easy fabricability, anti-static, easy cleaning, long-lasting and no seasonal effect. |

||

+86 18866930785 +86 15265936035

+86 18866930785 +86 15265936035